Textiles

If your production facility is suffering from process loss, low regain, yarn breakage, dust/fly, static build-up, then you need a humidifier. By properly humidifying you can increase productivity and profits. Correct humidity levels must be maintained in a production facility and storage area to prevent moisture loss from product, be it fibre, yarn or fabric, under production process or storage. This is possible by maintaining the required relative humidity of the inside ambient air of the production area which keeps the product in a moisture equilibrium with the conditioned air around it. The term moisture equilibrium refers to the relationship between the moisture content of the product and the relative humidity of the surrounding air, at which no further exchange of moisture takes place between the product and the air. Humidity being a function of temperature, the ambient temperature has an effect on this equilibrium moisture content.

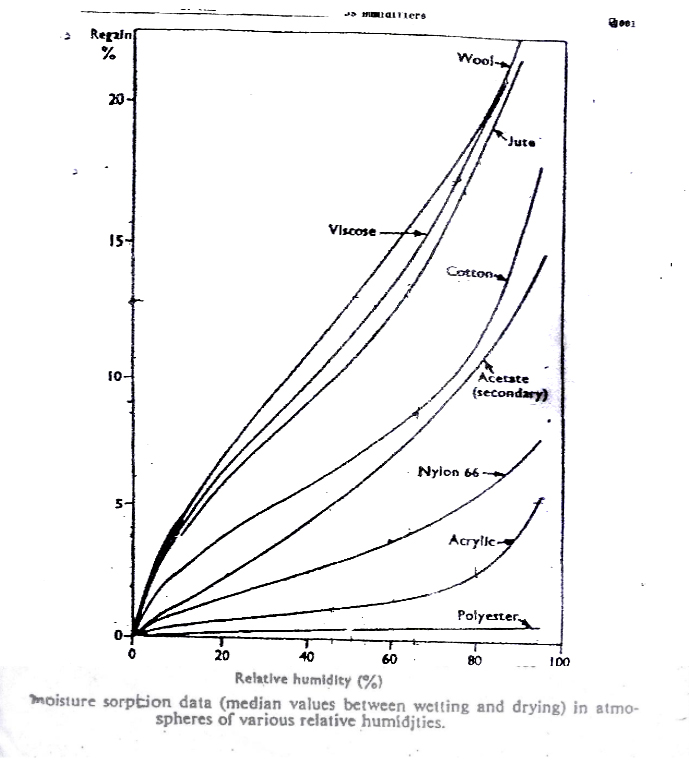

Please refer to the Sorbtion Isotherm chart which shows a relationship between relative humidity and moisture regain of various textile fibers (natural as well as man-made).

Yarns and fabrics react quickly to overly dry or overly damp air. Fibres become brittle, and fabrics shrink or stretch lengthwise or crosswise. This lowers the quality of semi-finished or finished products.

The threads are then at risk of breaking and produce an irregular woven fabric and clothes that lose their shape. Furthermore, textiles and leather goods are increasingly being manufactured in countries with challenging climatic conditions. It is all the more important to ensure a constant level of humidity in these countries and ensure quality and productivity in production.

Product weight, Static control, Productivity and Quality, Staff Comfort are all directly dependent on proper and efficient control of relative humidity in any production as well as storage facility.

Why choose Condair?

Condair’s comprehensive humidifier range offers a solution for any humidity control project. With the highest quality, operational and hygiene features, their reliable performance positions them as the first choice for leading companies worldwide, let alone Indian & Bangladesh.

The knowledge and experience of the Condair, the global leader in humidification, hundreds of successful projects in the different industries both in the Indian subcontinent and around the world, combined with the most advanced range of humidifiers available. All this is supported locally in the Indian subcontinent by Regent Machine & Servicing’s expert sales and engineering teams.

Optimum humidity control in a production facility will maintain the moisture equilibrium between air and textile, thereby eliminating evaporative losses from the product. As well as maintaining the final product weight and strength of the textile, this considerably reduces fibre shedding. Machine downtime due to breakages and re-threading is also minimised, vastly improving productivity.

As well as the direct benefits to the product, staff comfort is enhanced as the environment is cooler by several degrees and humidity prevents static-build up and dangerous electro-static discharge.

As demand for improved quality and productivity rises across the India textile industry, so does the need to enhance the complete factory environment – including the air quality. Humidity control in textile processing plays a vital role but is frequently overlooked with corners cut on quality. Humidification systems that consistently deliver the ideal environment for modern high-speed plant provide a rapid return on investment.

The environmental control inside a textile mill’s quality control laboratory also plays an important role in the future development of the production line. Typically these areas are small and need close humidity control to specific levels. Therefore in-room steam humidifiers, like the Condair RS that can maintain a room at ±1%RH, are ideal.

Benefits from proper humidification

Superior moisture regain levels in the product under process minimize makeup fibre input

Reduced fibre shedding and therefore wastage

Increase elasticity

Decrease in yarn breakage

Improved product quality through better yarn uniformity, reduced hairyness

Eliminates static electricity

Cool, clean, dust free environment improves staff comfort which in turn enhances productivity